Classic Rotary Vibrating Screen for Particle and Powder Classification and Liquid Filtration

Overview:

Rotary vibrating screen is also called round sifter, round screener, round vibro sieve machine, round gyratory screen, rotary screen, round separator, rotary vibrating sieve, vibrating sifter, circular vibratory screen, circular vibrating screen, circular vibrating sieve, gyro screen, gyro sifter, gyratory sifter, gyratory screen, gyratory sieving machine, vibro sifter, vibro separator, vibro screen, vibro grader, classic separator, vibratory separator, vibratory sifter, sanitary separators, filter sieve machine, industrial sifter etc.

This kind of screening machine does three-dimensional motion. It can be used in food, medicine, chemical industry, metals, mining, abrasive, ceramics, pigments, coatings, electronic materials, pollution treatment and other industries for wet and dry screening, sieving, grading, classification, filtering, cleaning, de-dusting, impurity removal, lump breaking, quality control and so on.

Working Principle:

Round separator adopts the latest vertical vibrating motor, which produces a horizontal, vertical and oblique vibration of three dimensional, and then directly passes the vibration to screen surface.

Changing the angle of the upper and lower eccentric block of the motor, it produces different exciting force, and the direction in which the material is running is changed.

The general characteristics of the vibrator adjustment are described below:

Gravity Angle | Effects | Main Usage |

| 0° | the raw material flows from the center line to the circumferential direction | Rough classification. Raw materials which are easy to be screened are classified in large number. Coarse grading. |

| 15° | start the vortex motion | Used for general screening |

| 45° | the longest vortex motion | Precision grading. Used for micropowder high condensation and high moisture content of the raw material classification |

| above 90° | raw materials concentrate to the center | special purpose |

Important Information You May Concern About Rotary Vibrating Screen:

| Model | AY |

| Shape | round |

| Layers of Screen | 1~5 screen decks |

| Mesh Size | above 325 mesh |

| Screen Frame | L type, adhesive type, ultrasonic type etc. |

| Mesh Cleaning Method | bouncing balls, ultrasonic system, rotary brush system etc. |

| Diameter | 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm |

| Material | carbon steel, stainless steel 304, 316L etc. |

| Function | grading, solid-separation, remove the impurity etc. |

| Movement | three dimensional vibration motion |

| Damping Spring | galvanized steel spring etc. |

| Motor | verticle vibrating motor |

| Motor Brand | China Made, OLI-WOLONG etc. |

Structure Diagram:

Features:

1. High efficiency, refined design and durability. Any powder and mucus can be sieved.

2. Easy to replace the screen, simple operation and convenience cleaning or washing.

3. The mesh is not blocked. No powder flying. And it can be sieved to 500 mesh or 0.028mm.

4. Impurities and coarse materials are automatically discharged and can be continuously operated.

5. Unique screen flame design. The service life of screen is long. Only 3~5 minutes to replace the screen.

6. Small size, not occupying space, and easy to move.

7. The screen of the machine can reach up to 5 layers, but 3 layers are recommended.

Basic Function:

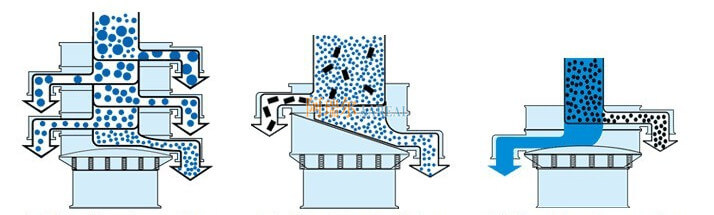

Grading & Sieving Impurity Removal Solid-liquid Separation

1. fine grading, control particle size range

Separating and screening of different particle sizes solid particle group with narrow particle size range

2. multi-group classification, control particle size range

Separating and screening of solid particle groups with different particle sizes, can be divided into five groups at the same time

3. coarse screening

Separating and screening large particles or ultra fine particles, and achieving high productivity

4. fluffy powder

According to the process requirement, the powder can be fluffy, so that the powder can be mixed into the air, easy to mix other materials

5. filtration and product recycling

It can be used to filter out the large particles in various slurry, or to dehydrate the solid-liquid mixture, or to recycle useful solid particles

6. wastewater purification and water pollution control

It can efficiently recycle useful solid particles and purify water for reuse

Technical Parameters:

Model | Power | Screen Surface Diameter | Effective Screening Area (m2) | Layers |

AY-400 | 0.18 KW | 350mm | 0.0962 | 1~3 |

AY-600 | 0.25 KW | 550mm | 0.2375 | 1~3 |

AY-800 | 0.55 KW | 750mm | 0.4416 | 1~3 |

AY-1000 | 0.75 KW | 920mm | 0.6644 | 1~3 |

AY-1200 | 1.1 KW | 1120mm | 0.9847 | 1~3 |

AY-1500 | 1.5 KW | 1420mm | 1.5829 | 1~3 |

AY-1800 | 2.2 KW | 1720mm | 2.3223 | 1~3 |

AY-2000 | 3.0 KW | 1920mm | 2.89 | 1~3 |

Overall Dimensions:

Model | A | B | C | D | E | F | G | I | Single Layer Height | Double Layer Height | Three Layer Height |

AY-400 | 472 | 372 | 150 | 400 | 110 | 60 | 300 | 270 | 550 | 660 | 770 |

AY-600 | 570 | 450 | 200 | 600 | 120 | 80 | 380 | 340 | 730 | 865 | 1000 |

AY-800 | 690 | 570 | 200 | 800 | 130 | 100 | 550 | 340 | 730 | 865 | 1000 |

AY-1000 | 810 | 690 | 250 | 970 | 150 | 120 | 650 | 400 | 790 | 925 | 1060 |

AY-1200 | 970 | 850 | 250 | 1170 | 180 | 130 | 760 | 450 | 860 | 1025 | 1190 |

AY-1500 | 1180 | 1060 | 250 | 1470 | 200 | 140 | 950 | 480 | 985 | 1180 | 1370 |

AY-1800 | 1480 | 1360 | 350 | 1770 | 220 | 150 | 1110 | 520 | 1030 | 1220 | 1410 |

Application:

Chemical Industry: PVC, citric acid, electrode materials, resin fertilizer, urea-formaldehyde molding powder, cosmetics, oil paint etc.

Pharmaceutical Industry: lactose, glucose, vitamins, traditional chinese medicine powder, preparations etc.

Metal and Mining Industry: alloy powder, molybdenum powder, stainless steel powder, tungsten powder, aluminum powder, nickel powder, cobalt powder, alumina, glass beads, graphite, kaolin, mineral salts etc.

Abrasive and Coating: aluminum silver paste, powder coating, iron oxide red, laser powder, pearlescent pigment, paper making coating, organic pigment carbon powder etc.

Electronic Materials: fluorescent powder, artificial black lead etc.

Food Industry: wheat bread, bread flour, sugar powder, milk powder, starch, juice, vegetable juice, monosodium glutamate, spices, yeast, seasoning, tofu, ice cream, chocolate powder, potato powder etc.

Pollution Treatment: waste oil and papermaking effluent, effluent from brewery waste water, dyeing and finishing wastewater, activated carbon etc.

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

Mobile Phone/WhatsApp/WeChat: 0086-15637361027

Reprint and contact the author and indicate the source:https://sifter1986.com/Classic-Rotary-Vibrating-Screen-for-Particle-and-Powder-Classification-and-Liquid-Filtration.html